What Makes a Tactical Pen Durable? Titanium vs. Aluminum Compared

Part 1: The Anatomy of Durability in Tactical Pens

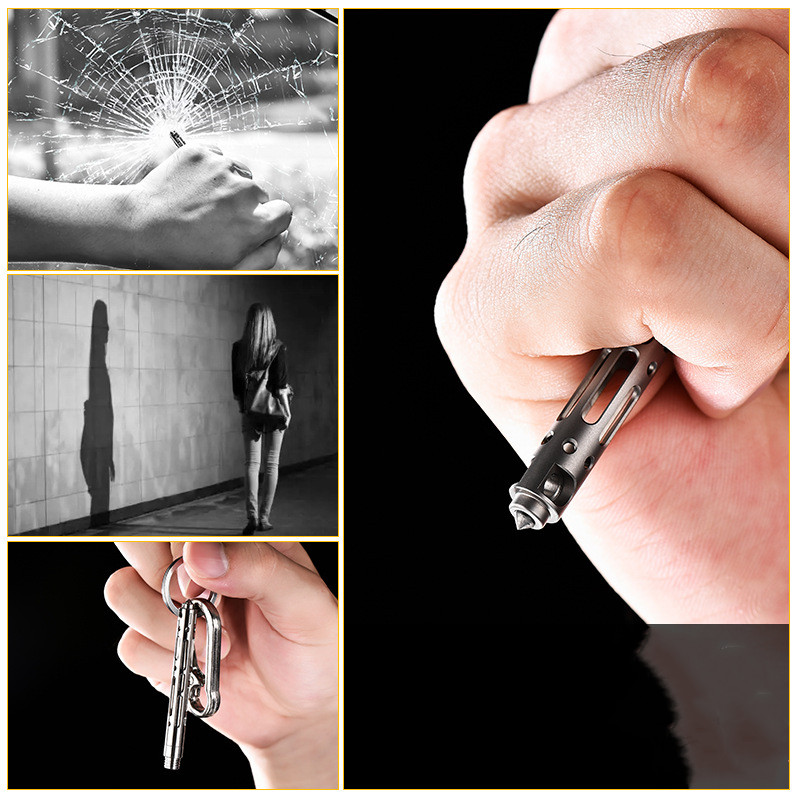

A tactical pen is more than a writing instrument—it’s a survival tool engineered to withstand extreme conditions while serving as a self-defense weapon. Durability hinges on three core factors: material composition, structural design, and resistance to environmental stressors. Unlike conventional pens, tactical variants prioritize resilience over aesthetics, ensuring they remain functional during impacts, drops, or exposure to harsh elements.

The choice of metal plays a pivotal role in defining a pen’s lifespan and performance. Titanium and aluminum dominate the market, each offering distinct advantages and trade-offs. Titanium, often dubbed the “space-age metal,” boasts unparalleled strength-to-weight ratios and corrosion resistance. Aluminum, while lighter and more affordable, relies on advanced alloys and treatments to compete. Understanding their differences requires dissecting their molecular properties, manufacturing processes, and real-world applications.

Beyond raw materials, ergonomic design influences durability. Features like reinforced seams, anti-rust coatings, and shock-absorbing mechanisms mitigate wear. A pen’s ability to retain its structural integrity under repeated stress—whether from striking, prying, or accidental drops—determines its reliability in crises.

Part 2: Material Showdown – Titanium’s Strengths and Limitations

The Science of Titanium

Titanium is a lustrous transition metal renowned for its high tensile strength (approximately 434 MPa) and low density (4.5 g/cm³). Its atomic structure enables exceptional load-bearing capacity without adding bulk, making it a favorite in aerospace and medical industries. In tactical pens, Grade 5 Titanium (Ti-6Al-4V) is the gold standard, combining titanium with 6% aluminum and 4% vanadium to enhance hardness and fatigue resistance.

Advantages in Tactical Applications

- Impact Resistance: Titanium’s yield strength allows it to absorb and redistribute kinetic energy, reducing deformation during strikes.

- Corrosion Immunity: It forms a passive oxide layer when exposed to oxygen, rendering it impervious to rust, saltwater, and acidic environments.

- Temperature Tolerance: Stable between -250°C and 600°C, titanium performs reliably in arctic cold or desert heat.

Trade-Offs

Despite its strengths, titanium has drawbacks:

- Cost: Titanium’s complex extraction and machining processes inflate prices by 200–300% compared to aluminum.

- Weight: Though lighter than steel, it’s denser than aluminum, which may affect portability for some users.

- Surface Hardness: Untreated titanium can scratch more easily than hardened aluminum alloys, necessitating coatings like titanium nitride for added abrasion resistance.

Part 3: Aluminum’s Role in Balancing Affordability and Performance

Aluminum Alloys – A Closer Look

Aluminum tactical pens typically use 6000 or 7000-series alloys, such as 6061-T6 or 7075, which incorporate magnesium, zinc, and silicon to bolster strength. While pure aluminum is soft and malleable, these alloys achieve tensile strengths rivaling low-grade steel (up to 572 MPa in 7075), albeit at a fraction of the weight (2.7 g/cm³).

Why Choose Aluminum?

- Lightweight Design: Ideal for everyday carry, aluminum pens reduce fatigue during prolonged use.

- Machinability: Softer than titanium, aluminum is easier to shape into intricate designs, enabling features like knurled grips or modular components.

- Cost Efficiency: Mass production and simpler processing keep prices accessible without sacrificing robustness.

Limitations to Consider

- Corrosion Vulnerability: Aluminum oxidizes when exposed to moisture, forming a powdery layer that weakens structural integrity. However, anodization—an electrochemical sealing process—can mitigate this by adding a protective oxide coating.

- Dent Susceptibility: Softer alloys may deform under high-impact strikes, compromising the pen’s striking tip or internal mechanisms.

- Thermal Conductivity: Aluminum transfers heat rapidly, which can make the pen uncomfortable to hold in extreme temperatures.

Part 4: Stress Testing – How Each Metal Performs Under Pressure

Tensile Strength and Impact Resistance

In controlled stress tests, titanium consistently outperforms aluminum in load-bearing scenarios. For example, a titanium pen can endure up to 1,000 lbs of vertical pressure without bending, whereas aluminum counterparts begin to deform at 600–800 lbs. This makes titanium preferable for prying tasks or defensive strikes against hard surfaces.

However, aluminum’s flexibility grants it superior fatigue resistance in dynamic situations. When subjected to repeated impacts (e.g., hammering or drops), aluminum alloys like 7075 can flex and rebound without cracking, whereas titanium’s rigidity may lead to stress fractures over time.

Environmental Durability

- Saltwater Exposure: Titanium’s inertness makes it the clear winner in marine environments. Even after months submerged, it shows no signs of corrosion. Anodized aluminum resists saltwater better than untreated variants but still risks pitting if the coating chips.

- Abrasion Tests: Titanium nitride-coated titanium pens withstand sandpaper scrubbing with minimal scratches, while anodized aluminum retains its finish unless subjected to sharp metal-on-metal contact.

- Thermal Shock: Titanium’s stability under rapid temperature changes (e.g., moving from a freezer to boiling water) ensures reliable operation. Aluminum may warp or expand, potentially jamming internal components.

Part 5: Practical Considerations – Choosing the Right Metal for Your Needs

Use Case Scenarios

- Military/Outdoor Survival: Opt for titanium if facing extreme climates, saltwater, or heavy-impact tasks. Its corrosion resistance and strength justify the higher cost.

- Urban Everyday Carry: Aluminum strikes a balance between durability and convenience, especially when weight and budget are concerns.

- Law Enforcement/Self-Defense: Titanium’s reliability in high-stakes scenarios makes it suitable for professionals, while aluminum suffices for casual users.

Customization and Maintenance

- Titanium Pens: Require minimal upkeep—occasional cleaning with soap and water suffices. Custom engraving or cerakote coatings can enhance grip and aesthetics.

- Aluminum Pens: Demand regular inspection for oxidation, especially around seams. Re-anodizing every few years restores corrosion protection.

Cost vs. Longevity

While titanium’s upfront cost is steep, its lifespan often exceeds a decade with proper care, making it a long-term investment. Aluminum, though cheaper, may need replacement every 5–7 years if used in harsh conditions.

Innovations in Hybrid Designs

Some manufacturers blend both metals, using titanium for high-stress components (striking tips, clips) and aluminum for the body. These hybrids optimize weight, cost, and durability, appealing to users who refuse to compromise.

By weighing these factors against your lifestyle and environment, you can select a tactical pen that aligns with your definition of durability—whether it’s titanium’s unyielding strength or aluminum’s adaptable resilience.